What is Stretch Wrap?

Stretch wrap also known as stretch film or pallet wrap is often confused with shrink film, however, they have very different properties. While shrink films must be applied with heat, stretch wrap is applied with a dispenser or pallet wrapping machine.

Stretch wrap, as its name implies, is a stretchable plastic film, commonly used to wrap products and cartons securely to pallets. It has elastic memory properties and clings to itself, leaving no residue behind. The four most common types of stretch wrap are cast, blown, high-performance and pre-stretched.

There are many stretch wrap options, clear stretch wrap is the most common but colour-tinted stretch wrap is ideal for international shipment to prevent pilferage or, for warehouse colour coding.

Opaque stretch wrap is available in black and white for use when product concealment is required or, to protect products from UV rays.

Airflow stretch wrap is a vented film, this breathable stretch wrap is used where air circulation is required for moisture or heat dissipation, outgassing or, to speed up cooling or freezing.

Specialty stretch wraps including anti-static, used to protect static-sensitive electronic products from static discharge and, VCI, used for protecting large metal parts or machines from rusting during transportation or storage are also available.

Custom printing is available on both hand and machine stretch wraps, increasing your promotional opportunities and security during transit.

Banding Film (Handy wrap stretch wrap)

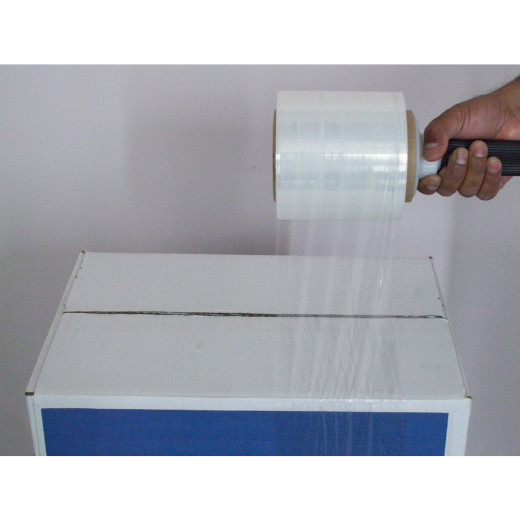

Mini wrap, also known as banding film or handy wrap, is the smallest stretch wrap, it is available in 3 to 5 inch widths. It is commonly used with a plastic handle in packaging applications as a cost-effective alternative to packing tape or lightweight strapping. It is quiet, easy to use and, it’s perfect clarity is ideal for product identification or scanning. Mini wrap is also available in pre-stretched material.

Hand stretch wrap for small to medium-volume users

Hand stretch wrap is probably the most popular of all stretch wraps, it is generally used with a dispenser although extended core stretch films are available, allowing for easy application without a dispenser.

Hand stretch wrap is also available in cast, blown, high performance and pre-stretched materials as described above. Its most common use is to secure products to pallets; hence its often referred to as pallet wrap.

For larger volume stretch wrap users we recommend using a machine for application.

Machine Stretch wrap is also available in cast, blown, high performance and pre-stretched materials, as indicated above. The main benefit of pre-stretched film compared with regular cast and blown films is that less film is required, therefore, there is less film to recycle when the pallet is unwrapped, making this a more environmentally friendly option. Also, more pallets can be wrapped per roll, meaning fewer roll changes.

Stretch wrapping machines increase productivity on your production line or in your dispatch area, as well as eliminate inconsistent hand stretch wrapping. Pallet stretch wrap machines are available in a variety of options including manual, semi-automatic, and fully automatic.

All three versions are available in turntable design, while semi-automatic and automatic versions are also available in rotary arm designs. There are then additional customized accessories available, including a loading ramp, weigh scale, loading conveyors, and more!

If pallet wrapping in different areas is required, battery-operated mobile stretch wrappers are also available.

At SmartShield, we strive to make our customers smile with packaging done right. With many stretch wrap machine choices, we recommend you contact our sales team, who will assess your application to ensure you invest in the machine that best meets your performance requirements.

Stretch wrap comparisons:

CAST HAND STRETCH WRAP

| |

Thickness

|

Recommended for max loads of approx.

|

|

Regular Duty

|

Up to 70 gauge

|

1000 Lbs

|

|

Medium Duty

|

Up to 80 gauge

|

2000 Lbs

|

|

Heavy Duty

|

Up to 90-120 gauge

|

2000 Lbs +

|

|

Extra Heavy Duty

|

120 gauge +

|

2000 Lbs +

|

BLOWN HAND STRETCH WRAP

| |

Thickness

|

Recommended for max loads of approx.

|

|

Regular Duty

|

Up to 65 gauge

|

1000 Lbs

|

|

Medium Duty

|

Up to 75 gauge

|

2000 Lbs

|

|

Heavy Duty

|

Up to 80 gauge

|

2000 Lbs +

|

|

Extra Heavy Duty

|

90 gauge +

|

2000 Lbs +

|

HIGH PERFORMANCE HAND STRETCH WRAP

| |

Thickness

|

Recommended for max loads of approx.

|

|

Regular Duty

|

Up to 40 gauge

|

1000 Lbs

|

|

Medium Duty

|

Up to 47 gauge

|

1000-1500 Lbs

|

|

Heavy Duty

|

Up to 59 gauge

|

2000 Lbs

|

PRECISIONRAP HAND STRETCH WRAP

|

Regular Duty

|

recommended for maximum load of approximately 1500 Lbs

|

|

Heavy Duty

|

recommended for loads over 1500 Lbs

|

CAST MACHINE STRETCH WRAP

| |

Thickness

|

Recommended for max loads of approx.

|

|

Regular Duty

|

Up to 70 gauge

|

1000 Lbs

|

|

Medium Duty

|

Up to 80 gauge

|

1000 - 2000 Lbs

|

|

Heavy Duty

|

Up to 120 gauge

|

2000 Lbs

|

|

Extra Heavy Duty

|

120 gauge +

|

2000 Lbs +

|

BLOWN MACHINE STRETCH WRAP

| |

Thickness

|

Recommended for max loads of approx.

|

|

Regular Duty

|

Up to 65 gauge

|

1000 Lbs

|

|

Medium Duty

|

Up to 75 gauge

|

1500 Lbs

|

|

Heavy Duty

|

Up to 90 gauge

|

2000 Lbs

|

|

Extra Heavy Duty

|

Up to 120 gauge +

|

2000 Lbs +

|

HIGH-PERFORMANCE MACHINE STRETCH WRAP

| |

Thickness

|

Recommended for max loads of approx.

|

|

Regular Duty

|

Up to 45-55 gauge

|

1000 - 1500 Lbs

|

|

Medium Duty

|

Up to 60-70 gauge

|

1500-2000 Lbs

|

|

Heavy Duty

|

Up to 80 gauge

|

2000 Lbs

|

|

Extra Heavy Duty

|

80 gauge +

|

2000 Lbs +

|

* Please note: all maximum load capacities are based on the recommended wrapping pattern for a secure pallet: 2-3 rounds at the bottom, 30-50% overlap as moving up the pallet, and 2-3 rounds at the top

Blown Stretch Wrap Versus Cast Stretch Wrap:

|

|

BLOWN STRETCH WRAP

|

|

CAST STRETCH WRAP

|

|

*

|

High density = high tear and puncture resistance

|

*

|

Lower Density = lower tear and puncture resistance

|

|

*

|

Won't re-stretch after application

|

*

|

Stretches easily, may allow product shifting as can continue to stretch after application

|

|

*

|

1-sided cling, greater load retention

|

*

|

2-sided cling, lower load retention, product or pallets cling to each other, providing greater security

|

|

*

|

Less stretch capacity

|

*

|

Higher stretch capacity (Greater yield = more products or pallets wrapped per roll)

|

|

*

|

Nosier unwind

|

*

|

Quieter unwind

|

|

*

|

Not crystal clear (a little hazy)

|

*

|

Perfectly clear for easy product identification and scanning

|

|

*

|

More expensive

|

*

|

Less expensive

|

|

*

|

Strong stretch memory (requires more force to stretch), loads stay more secure

|

*

|

Lower stretch memory (requires less effort to stretch), load may shift over time

|

Cast film tends to be a more cost-effective stretch wrap choice as the manufacturing process is a lot faster than blown stretch film, however, blown stretch wrap offers greater durability and holding powers, therefore offering more security for heavier or larger loads.

What are the benefits of pre-stretched stretch wrap?

Pre-stretched stretch wrap is exactly what its name suggests, and it is a film that has been pre-stretched to approximately 90% during the manufacturing process prior to being wound on the roll. It is, therefore, commonly thinner material (lower gauge).

There are two main advantages of pre-stretched stretch wrap:

- One that productivity is increased, more pallets can be wrapped per roll, meaning less roll changes.

- And, two; maximum material use is attained, meaning less film is required, making it more environmentally friendly than alternative stretch wraps.

Would your company benefit from using Precisionrap pre-stretched hand stretch wrap?

Click here for more details on Precisonrap.